The RMIT research team combines medical mask scraps with recycled concrete to create a material that can be used as road construction material layers.

Masks, after being collected and disinfected, are cut into small pieces of 2 cm in size to combine with the materials for the upper and lower foundation layers. The crumbs that make up the asphalt layer are grinded into powder by the team.

The material is then heated at 75 degrees Celsius. This step also ensures that the material is completely clean of bacteria, and evaluates the elongation and tensile strength when exposed to large amounts of heat. Dr. Mohammad Saberian, a member of the research team, stated that the heating process would help the material improve the elongation by up to 118.91%.

Used construction mortar was processed into recycled concrete by the team, including stone, brick, and concrete, with suitable fineness and sand content. After that, the concrete reinforcement is mixed with the amount of processed masks. The team carried out tests to find the right mix ratio between good cohesion between the two materials.

By gradually increasing the ratio, the mask material content is determined at 1%, the total recycled concrete aggregate accounts for 99%, this mixture maintains a good bond between the two materials through tests in terms of pressure, strength, deformation and dynamic properties, meeting relevant construction specifications.

The finished product is made from two recycled materials. Photo by RMIT.

The finished product is made from two recycled materials. Photo by RMIT.

"The percentage of 1% of recycled mask scraps in the mixture is small, but has the highest elastic value when combined with concrete reinforcement," Dr. Mohammad Saberian told VnExpress. He said that the addition of masks to the recycled concrete reinforcement helped to strengthen the material layer, and at the same time solved medical and construction waste. However, too much mask crumbs could affect the resistance and elasticity of the road layers.

The road is made up of four layers: subgrade, base, sub-base and the top layer of asphalt. The layers must be both hard and crack resistant to withstand the pressure of large trucks. Therefore, the processing of mask materials must ensure a certain smoothness and porosity.

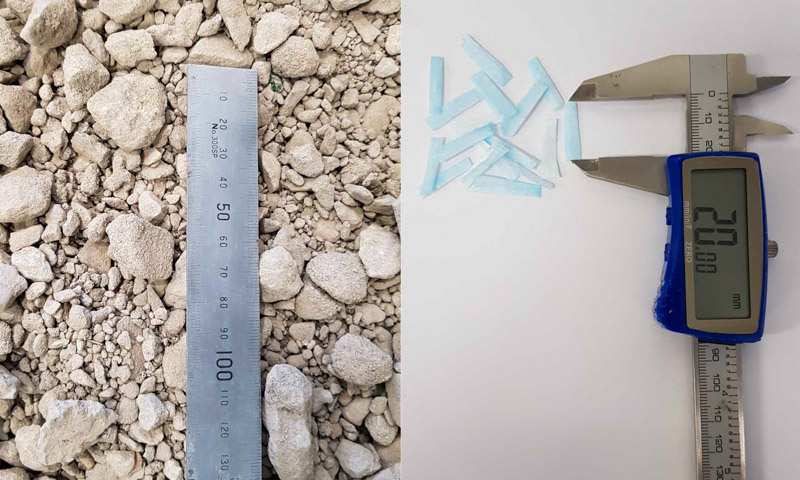

Recycled concrete (left) and mask scraps are mixed for recycling. Photo by RMIT.

Recycled concrete (left) and mask scraps are mixed for recycling. Photo by RMIT.

The research team also pointed out that 1 km of two-lane roads, if made of materials combined with recycled masks, will require up to three million used masks, solving a large amount of masks discharged into the environment.

Currently, the team continues to improve the parameters of the mixture to make a complete prototype line. Scientists will study the potential of medical masks in the production of recycled concrete and asphalt. In addition to masks, a number of personal protective equipment is being assessed by the group for suitability for recycling by this method.

By Nguyen Xuan, Vnexpress.net